Hello fellow modelling enthusiasts of all scales and types! Obviously, I have not been active on the old blog, or in the hobby for that matter, lately. As this weekend is sort of the one year anniversary of the 'end of Quinntopia' I thought it might be nice to provide an update on "Quinntopia: The Reboot".

Except there isn't one. Yeah, I really have not made much progress. I have had ambitions - and a few false starts - of using layout design software to create my next layout, but each time I keep creating the same layout I had before (and / or far larger than I really want) or too minimal and not at interesting enough to get motivated with the carpentry.

So...the dark ages of Quinntopia continue.

But I had a sort of epiphany...what if 'planning software' is my problem? After all, the original Quinntopia began (and continued to grow) without any software planning (I did go back in and retroactively recreate it in RRTrack just so I could have a plan to work with). This led to a much faster creation to train-running time period, and was far more satisfying than a plan on a computer.

So I may take that approach. But not without any sort of limits - I sort of know what I want after my experiences with the original Quinntopia, so I plan to make a mental list of those things and be disciplined about sticking with them. Some of those 'best practices' I established in my 'mistakes' post, for example, while it does not need to be mobile, it can't be permanent. I don't want it so large that it dominates my entire room. I want as much 'main line' for train running as possible, and finally, its an urban layout, so start with the city and work the tracks in and around the structures.

So here's my strategy: Start with a module that will fundamentally be the city - all the buildings, cars, and lighting that that entails. From there, configure the tracks as if they were passing through an urban area.

Simple, right? Well, we'll see if simplicity is better motivator for getting a layout back in the world versus thinking about it!

On a more personal note, you may be surprised that the ruler of the kingdom of Quinntopia is a human just like everyone one else and was subject to distractions which kept him from the development of his benevolent dictatorship; I found myself on the receiving end of one of those 'reduction in force' discussions last Fall. Yes, I was 're-tooled' or something! So for much of the quiet period this past year I was out networking and applying for new roles, etc.... The good news is that I am now gainfully employed again with a great, new employer. The bad news is that the job requires more time and a bit longer commute than I previously had, so precious discretionary hours for hobby-related interests are a bit more difficult to find.

In the meantime, I hope you enjoyed the detailed and fascinating (and somewhat amazing) story of Terry's repair of a Rivarossi Chapelon locomotive that he has been sharing on this blog over the past couple of months. It was fun to see that story and share Terry's experience. If you have something you'd like to share on my blog, drop me an email at quinntopia at hotmail dot com and we'll see if its something other readers would like to read.

I hope this won't be my last post in awhile but life can be interesting!

Thanks for reading !

5.25.2015

5.21.2015

The Italian Job: Rivarossi French 4-6-2 Chapelon Rebuild: Part 3

Here is the third and final part of Terry's journey to rebuild a Rivarossi Chapelon that he bought on eBay from...me!

For Part 1 click here, for Part 2, click here, and for my original blog post when I first added this same loco to my collection years ago. Jerry/Quinntopia

As told in Part 2, the arduous task of solving the Smokebox/light removal and repair issue was being solved by Terry:

Final apologies to The Italian Job and The French Connection.

There are two missing ears on the threaded shaft insert that secures the post in the above photo; that is another reason I did not go to a full disassembly of the chassis and apron. That defect was not my doing. But it was evident I would need to be cautious in that area.

With a few refinements and adjustments I then dry fit assembled the locomotive to test the lights. I had already done several prior fits to ensure it was progressing well. And with a little 12 V juice they lit. It was a marvel. The lights were operating and back to their original configuration. This view shows the apron lights illuminated.

Now this gets me to wondering just what the French engineer and fireman were looking at in those days or nights. My cynical conclusion was probably not too much. Maybe this engine was intended to run clandestine excursions in cover of the night or darkness. But I suspect that field of forward vision in one of the smoking beasts at full steam was not very good. At this point of the rebuild I still needed to add more black paint to the rear interior of the smokebox to hide the light channeling through the CA glue and brass tube recesses. That since has been completed.

Once I was assured through fitting that the smokebox cover would not hit the lightbulb and bracket, I then used two tiny drops of CA glue to secure the cover to the boiler front. Some might advise against this, but it was not fitting secure enough to be held in place on its own.

And I did not want to lose that item. It needed to be secured. Besides, the light bulb was not made to be accessed from the front. One needs to remove the boiler from the chassis apron to get to its mechanics.

By this point I had also attached the cleaned air tanks to the upper boiler shell.

I used CA glue very cautiously. And once secure I placed small dabs inside the shell where the pins sit within the shell. By comparison to other similar vintage locomotives, I realize I may have inverted them. But it seemed that was the only way the tabs protruding from the tank bottoms fit within the holes on top of the boiler. Now that is a testament to futility. But ‘she is as she is’. I thought I had researched that well enough, but surely not. And I can only guess what picture I used for that final check to secure them. At least they are straight. And it is too late now; I will not attempt to reverse that move.

Next it was time to get the weight rod assembly installed.

Recall that the locomotive shell itself does not house the motor (or the ‘zamac’ thankfully). However, that renders it quite light in weight. And if things are out of alignment, I envision, and there are some reports, that the finely working tender driven motor at full steam will push that light engine shell right up and off the narrow track around a bend. Like a crab, moving crab-legged with legs scurrying sideways beneath the water. After all that careful work, if it hits the concrete floor you now have a true static display with plenty of spare parts for another. Fortunately it seems a rare occasion to have a good tender and locomotive combination. So if you are lucky it will either work correctly or not at all. All or none.

From all the prior work it was apparent the steel rod fit too snuggly within the boiler shell. It needed clearance. I filed the edges and top corners of the rod and screw that holds the headlight bulb contact blade.

The small clip at the lower right of the picture is screwed to the bottom of the weight rod once it is positioned inside the boiler. That spring clip carries power from the rear of the chassis and drive wheels up through the weight rod forward to the bulb base through the fine metal spring blade that contacts the bulb base center post. Here is a picture from earlier in the build that shows the narrow confines within which this all operates.

I also filed the inside of the boiler shell with a fine rat tail file. With time the rod was free to move inside.

As I noted earlier, after careful fitting, I had secured the front smokebox cover to the boiler shell. So the weight rod could no longer enter from the front of the boiler. But the rear of the shell in the cab has another opening that is covered by the coal bin doors. I will touch on that part of the rebuild a little later. That opening allows access of the weight rod and its workings from the back end of the locomotive boiler shell.

It was also necessary to make some allowance on the interior recess of the bottom boiler to accept the slightly larger lightbulb post base solder points.

I used a small file for that work...

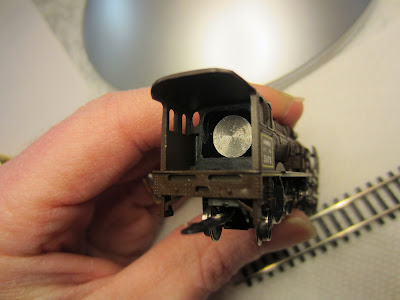

These pictures show the nearly completed locomotive:

The front left baffle or side smoke shield has not yet been attached. The latter picture shows the small size of this locomotive. With very careful application (via a toothpick tip) I used CA glue to attach the left front baffle or side shield.

Note that the rear protrusions from the baffle side shields clip over two pins on the boiler sides. This raised recess on the right front baffle is evident in the left center of this picture.

These are not glued. But rather press fit and ‘hold’ the boiler front within the shields.

The picture above also shows the freshly painted front boiler cover. I realize it is still a little rough. But I have not yet decided how much to refine that. And there is still the question of whether or how I might add the Chapelon Herald that sat front and center on that cover. Sadly, that was turned to drilled plastic dust many years ago. The right front buffer (or bumper) still needs to be attached. It has survived and at this stage of the rebuild currently lives inside a plastic medicine bottle inside a candy box lid, inside a cigar box. (Ok, ok I confess. At this point I am reminded of Phil Hartmann, as the Anal Retentive Carpenter or preparing a Thanksgiving dinner as the Anal Retentive Chef on early Saturday Night Live (SNL) skits. If you have not seen those, give it a shot. I still recall them as some of the funniest of those days. But I have learned it is best not to lose some of these small detail pieces. They are quite difficult to find or reproduce.)

With some careful use of CA glue, I reattached the front buffer or bumper.

If you look closely at the bottom of the re-installed front right buffer, it is apparent that the gloss white paint was missed on the lower edge from the factory. Careful application of gloss white Testers enamel with a 3O brush corrected the problem.

Next I set about to ensure the boiler coal cover doors fit a little bit tighter. I mentioned earlier in the story that the boiler weight rod slides inside the boiler shell. When assembled from the factory I suspect it had the option of either end. But the front smokebox cover was quite loose in fitting. So I lightly glue it. This left the reverse end of the boiler shell to allow removal if need be of the weight rod.

I carefully placed some cyanoacrylate glue on the left edge of the boiler door recess inside the cab. I did not set the doors in when wet. Instead, I allowed the glue to dry fully. I wanted to create a slightly narrower channel to receive the rear cab inside boiler cover doors. I then fit the doors and carefully scraped any dried excess glue to allow the doors to sit tight.

Here are a few pictures showing the completed locomotive rebuild....

Here is a shot of the final locomotive with lights ablaze.

These photos show the completed locomotive and tender.

That concludes the journey of rebuilding one (of I anticipate thousands) of these vintage Italian Rivarossi N scale locomotives. It has been a challenging and a rewarding adventure. I have met several new friends, gained new knowledge and a new skill (although my wife might not necessarily agree). It also reminds me of days of my childhood, watching my father toil away at some of these fine little machines. Adjusting, lubricating and getting them to a better place. And that is a heart warming memory. Sometimes with dry eyes, sometimes not. I now realize that many times he was working on these late into the evening while my brother and I were likely sleeping.

For reference here is a shot of this particular locomotive as she was found.

Perhaps this particular French SNCF 231 Chapelon (4-6-2) might get to go to the prom after all.

Until we might meet again I wish you all well.

TJZ

Completed 4/26/2015

-----------------------

Terry - thank you so much for sharing this terrific story and impressive restoration effort on a beautiful locomotive! Well done and 'le felicitazioni'! - Jerry/Quinntopia

The Italian Job: Rivarossi French 4-6-2 Chapelon Rebuild: Part 2

After a couple of months of delay, here is Part Two of "Terry from Delaware's" quest to rebuild his Rivarossi locomotive that he bought from some cad on eBay (uhh...that cad was me! Strange story right? No, I did not know Terry before he won my eBay auction).

The good news is that Terry completed his rebuild of this loco! I hope you enjoy this post, please check out Part 1 here, and my original blog post when I first added this same loco to my collection years ago. Jerry/Quinntopia

Even more apologies to The Italian Job and The French Connection.

The story and completion of the rebuild and refurbishment of

this Italian made N scale French locomotive picks up with part 2 of 3. And I

must make an admission or confession. Those reading the first part of this tale

may recall my recommendation not to throw away anything during a disassembly or

rebuild. Throw away nothing.

That is still a good idea, but in the past it seems I have

ignored my own advice. Maybe that was before I fully realized the value of

keeping things. Or not having the sharp eye for a second use or rebirth of an

item of object.

The value in keeping a small scrap or odd item is a trait

that I learned from my late father. But don’t get the wrong idea. He was not a

pack rat. But he did have a knack for holding on to certain things. And he was

wise and thrifty. Low and behold many of those ‘saved items’ found a second

use. This is a smart and frugal behavior I learned from Dad and I am glad I

have that characteristic. So in the case of this rebuild, the item of utility

might be surprising. It is not a screw, washer, wire, bulb, or other oddity. It

is not a new or replacement item made by Rivarossi or another N scale

locomotive maker. No nothing of the sort. The item I refer to are those older

format 3 ½ inch floppy disc cases. The older black case color in particular.

One might ask “what on earth could that have to do with a train rebuild?” Read

on.

Part 1 ended with having soldered the new upper light bulb

mount to the original cut stump remaining on the locomotive chassis apron. It

was a good effort and helped turn the corner on this project.

Next I looked over the remaining pieces and pondered their

refinement and reassembly. It is a good idea to work slowly. This is for two

reasons. Some steps may be irreversible. Hence you cannot backtrack. The second

reason is that I was unfamiliar with the original assembly of these Italian N

scale trains. And for that reason, if some steps are not irreversible, others

may be permanent or fatal. Then it might be necessary to go out and buy

another. That may be a poor option too. And I often remind myself of Aesop’s

fable of the tortoise and the hare. Remember, the tortoise won the race. Slow

and steady wins the race is a mantra that I like to say.

I set about the work on the cut boiler tube. If you look at

the sixth picture in part 1, it is evident that I had to sever or cut though

the small plastic pin or tube that protruded down through the chassis apron

into the piston or valve head body assembly. I was determined to replace that

cut pin. Working with the wire gauge drill bits and the fine point X-Acto knife

I cleaned out the portal in the chassis apron. I carefully drilled out the

bottom of the boiler tube bottom end with either an ~80 or 90 wire gauge drill

bit (if I recall correctly).

Now for that prized item of which I had previously thrown

away about 30 cases. The 3 ½” floppy disc. I believe they are made of ABS or a

polystyrene based plastic. My understanding is that is similar if not the same

as the shells of many of the early Rivarossi and similar scale locomotives. So

I set about to make a new pin.

My first ‘second use’ and interest in the floppy disc cases

actually arose from a desire to practice N scale decaling or lettering. One of

my other goals is to build certain locomotive and passenger car combinations.

Some of those ‘liveries’ can be purchased and others are less often seen for

sale. So I wanted a canvas or practice surface. If I was planning to paint a

loco and tender shell, and then either decal or stencil lettering or other

decorative ornamentation I did not want to practice on an ‘A+’ grade item. No I

needed practice. Enter the floppy disc cases. But that will be the subject of

another build. For now I need to finish this Italian - French connection.

I stripped open a few cases and removed the electronic,

spring, and soft wiping wafer guts. This left only the two outer clam shells or

halves. An added bonus inside those case shells, are ridges and grooves of

varying thickness. So with a little research, testing, and cutting and

assembling chips I found that cyanoacrylate (CA) glue and Plastruct solvent

weld are two good means to glue these ABS cases and components together. But those

two solvent or glues work and function very differently. So depending on the

need a different mode might be needed. For example, the Plastruct solvent is

quite good at softening the ABS or polystyrene and will give a fairly good bond,

although perhaps not rigid strong. Generally it will not leave a haze or cast

residue or sheen if carefully applied. But, it will also soften or dissolve. So

if you don’t have much to work with and only a small piece that can be a

problem. If you are not careful, everything will collapse to a dark or

blackened morass in front of your eyes. So be very careful if you are trying to

reconnect thin tender grab rails or the front pilot of a Berkshire or a Mallet

with a ketone-based solvent. Because once gone – they are gone. Some good

advice I obtained from one of the guys at Nicholas Smith Trains in Broomall,

Pennsylvania, was use a very fine detail brushes. Like a 3O or 4O. That is wise

advice. (PS. - if you want to visit a neat train and hobby shop with just about

everything, then you need to get in their store. I don’t think you will be

disappointed.)

The CA glue is also good, but use it where it can be hidden.

It tends to have a sheen and thickens since it does not dissolve the ABS. So it

must be used sparingly. (Remember the boiler shell CA glacier I had to work

with previously.) So the trick is to gauge what you need. Sometimes trial and

error on expendable items is needed.

To fashion the pin I shaved and chipped at the inner ridges

of the floppy disc case. Doing so you quickly learn that the thin ABS can curl

or roll. It does not have much dimensional stability. Slow careful work with a

razor sharp blade is essential. Otherwise you will have black, inedible shave

ice that would not be palatable. And since I needed a round pin, I first used

the blade and through scraping I rounded a large portion of the ridge before

severing it from the case. In short time I had a few suitable pieces. Whatever you do don’t sneeze or leave the table. They will be gone when you

return.

For reasons explained above I decided to use the CA glue to

position the pin inside the drilled cavity. Once dried I would then carefully

scrape away any excess. With a little CA, some adjustments, and time I had the

pin completed. At this point it is still evident which one is glued in. I then

set that aside and let it dry.

Now it was time for the next big challenge. The reappearing

front smokebox boiler cover. Those reading this story will recall the surprise of

finding that item still attached to the locomotive boiler shell. Granted it had

been ground, drilled through, installed backwards, and had a brass tube

protruding through it – but it was there. Damaged goods but it was not missing.

The brass tube escutcheon was cut at an angle. How would I get this sorted?

So I headed to the basement to ponder this next step. This

detail piece is much smaller than a dime. With all the work items and dark

crevices, boxes, etc. in the basement I decided that working there would be a

bad move. This little piece would head off somewhere to never appear again. Many

of us working with these small gauge trains will know this all too well. A

small spring or screw gone, forever. Not to Davy Jones locker, where it might

wash up with the tide, but instead somewhere far away, out of sight, out of view. Gone, but

near and irretrievable. For that reason, one of my odd tricks, I sometimes work

inside a small chocolate candy box or cigar box. It works quite well. (Now - and

this is not a product placement - but if you are looking for good chocolate,

check out Hughes Home Maid Chocolates from Oshkosh, Wisconsin. Ok, maybe this

is a plug. But I get nothing from this, other than passing along this wonderful

source. They are located on Lake Winnebago in Wisconsin. And the best part, if

you eat the candy quickly you will have that wonderful box and lid to retain

and store those small items. If you look at picture 10 in part 1, showing the

pieces in a small white box, that is a Hughes Chocolate box lid. One of our family

friend’s sharp eye caught that right off the bat when they read part 1 of this

story. I apologize for the digression, but it really is good chocolate.) So I

shut off the basement lights and headed back upstairs.

I figured a solution to work up the smokebox cover. First I

would secure it and then carefully cut it with an X-Acto saw blade.

Careful work with a small flat file and it was getting to a better place.

After some final cleaning and polishing I filled the inside reverse

side of it with a metallic epoxy and let it sit and cure.

These next pictures show the gathered pieces in various

stage of repair and rebuild. The first

was taken just prior to my having soldered the light bulb post. The second

before the air tanks were set in place.

Next I returned to final fitting and positioning of the new

light bulb mount within the boiler shell. This took many clips with snips,

filing, and careful adjustment.

I then returned to the cured smokebox cover. It quickly became apparent that the inserted brass tube protruded too far into the boiler shell front. Hence it would not sit in proper position. Thus I would need to remove a large portion of it from the inside recess. How was the question? And in reflecting, this is perhaps why it had been installed in reverse in the prior work.

This is where another little odd “Life lesson” entered into

the crevasses of my mind. A “Life lesson” is a term that my eldest daughter

uses to describe something that we should pay attention to, something of note.

And I agree with her entirely. For this project, I had visions of that small,

sacred, smokebox cover flying across the basement never to be seen again as I

worked with it. And if that happened, with already considerable time and effort,

as well as money spent and no spare or back up – I would be out of luck. It

would be one of those irreversible moments. So what do I do?

For some reason I recalled rebuilding a lawnmower in

Yorktown, Virginia as a young teenager. Yes – an odd story from decades ago but

it was fun and it brings back great memories. And it had a present day message,

a life lesson. As that young teen some decades ago, I was given an old ~20 inch

4-stroke push mower by a neighbor and family friend. It had sat outside in his

front yard for years. It was ‘solid as a rock’. So of course I accepted the

gift and the challenge. (Remember, I can’t pass up the odd item. And the price

was right, it was free.) So I pushed it home. That was a project for my father

and me to tackle. We did and it was fun. We took it apart, freed the stuck

piston, rebuilt it, put in new rings, ground the valves, and she was ready to

go. Well almost. There was a reason it sat there those years. The recoil

starter spring had broken. Now that was a challenge. The small end with two grooves

that held the spring securely in the metal housing had snapped. What to do?

Without being held securely, you got one pull and no recoil; the spring was not

held or coiled so it would not rewind. And if the engine did run, trying to

carefully recoil the starter rope on a running engine is not advised. It is probably

a good way to lose fingers or fingertips. So at about age 12 or 13 I tried to

figure it out. And I did. I clipped two small grooves in the end of that

spring. I would simply reattach it in the cast housing, put it back together

and all would be well. And then I tried to reassemble it. Well, if you have

ever tried this, I offer the best solution. Have someone else do it. Pay them. Pay

them well. I chased that slithering sharp serpent all around the garage for

about a half hour. And what is worse, it is hardened or blued steel. And it is

sharp, has a strong memory, and will whip and snap like a caged bull or worse. But

I was determined and I finally got it. The trick. I used what we have always

called ‘sugi wire’. It is the 30 or 40 thin single strand bright color-jacketed

phone or communication copper wire cables that were housed in a ¾ or 1 inch

gray vinyl sheath. I pulled single strands and tightly wrapped that spring in

several strands of the wire, getting tighter and tighter with each twist. And

somehow I got it wound tight, set the new ‘grooves’ to hold that coiled strand

in the housing, got the coil spring fully rewound, reassembled, and

functioning. And I used that mower for about the next four or five years mowing

lawns. So the moral of the story, or the “Life lesson” was ‘secure your work’.

Why that story entered my mind as I sat at the kitchen table figuring how to

fix that smokebox cover I will never know. But that is how it happened. And it

saved me from losing that irreplaceable smokebox cover.

The solution - I would invert the smokebox cover, duct tape

it securely to a board in my vise. I then used a punch to cut a circle in the duct

tape and then used a Dremel with a small grind stone to remove most of that

inner protruding brass tube.

It is not pretty but it would be

hidden. And best of all, it did not wind up somewhere lost in my basement. Here

is a good picture of the completed lightbulb post.

To Be Continued!

See Part 3 for the stunning conclusion and final assembly of Terry's Rivarossi Chapelon!

Labels:

Locomotives,

nostalgia,

RIVAROSSI,

SNCF,

steam,

tips+tricks

Subscribe to:

Comments (Atom)