STEP 8

Step 8. Sort of. You see at this point we're going to relying on a bit of creativity. As I mentioned in my last post (Steps 4 through 7) there are no instructions with my kit on how to add the additional 11 story 'add-on' section to the main 16 story section.

In Steps 4 through 7, I explained how I added each floor into the 4 grooved vertical strips, and then placed the 'roof' soffit piece on top. Its the same process for the 16 and 11 story sections.

The instructions for Step 8 in my original instructions disuss how to start adding the top floor and interior walls, which we don't want to do just yet until we figure out how the original kit and the additional structure go together.

Nevertheless, here is the original German and English translated instructions for Step 8:

German:

8. In die beiden Kern offnungen schiebt man jetzt die

geraden Kernwande Fb mit den Türöffnungen bis an die Unterkante der Bodenplatte

( leichtes seitliches Verschieben erleichtert das Durchstecken) An der

Bodenplatte wird die Kernwand angeklebt.

English:

In the two core openings to push the now straight core walls Fb with the door openings up to the lower edge of the bottom plate (slight lateral displacement facilitates leadthrough) On the bottom plate is the core wall glued

Instead of following those instructions, what I am going to do is:

- Insert the 'center wall' sections into both the 11 and 16 story sections

- Apply the clear window plastic

- Apply the exterior walls

Adding the Interior Walls:

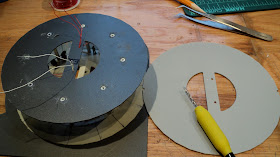

There are two long, flat strips with door-sized cut outs for each 16 and 11 story section. These should be inserted first. These are pushed down through the top semi-circle all the way down each floor until they extend into the holes in the bottom section (they should be flush on the bottom and - eventually - the top [whereever that is, at this point its not clear given we're going to add a section to the top of this])

In the photo below I have the above 2 flat, smooth sections installed which are behind the 'corrugated' sections (in blue) which get inserted after you have the flat sections in. I added some notes to the below photo which I hope help. IMPORTANT - This photo was taken after the clear, plastic 'windows' were applied...you DO NOT want to insert these interior walls after you apply the windows. You may need to stick a pencil in between the flloors to get these 'interior wall' sections all the way through each semi-circle hole on each floor, and if you have the clear plastic windows installed, you will be stuck!

Apply the clear window plastic:

This is probably one of the steps I hated the most.

I was fortunate to find a really good glue / adhesive for this step, again I used "Welder" - as I mentioned back in Step 1, its a clear, gel-like substance (but its NOT invisible! You will see streaks and other gooey-ness you still don't want to be showing on your model!) but it has a good, rubbery adhesion that seems to be effective fairly quickly - which is really nice when you are gluing something around a cylinder and want it to stay in place! It also won't 'fog' your clear plastic like CA will, and works much faster than traditional Plastic Cement.

The trick with the window sheets is that they have rectangular window frames already on them, so that tells you where the 'windows' will go, but you also need to apply it so that none of your floors, or any of the four vertical strips are in these windows. I was succesful on the former but, as I mentioned in an earlier step, my vertical posts ultimately are slightly askew and its impossible not have some of them showing through some of the windows. Bummer.

I tried to carefully apply a little bit of glue around the exterior of most of the floors, then - without letting any window area contact the glued floor (I want the glued floor edges to go between the window spaces) - wrap the plastic sheet around the entire structure. And pray.

Actually, have some tape handy to hold the plastic sections firmly in place while the glue sets.

I waited 24 hours before moving on to the next step.

Apply the walls!

This was a confusing step. The wall sections come as a complete sheet, and the instructions and photos that accompany them seem to indicate taht you should glue the two edges together to form a sort of 'hollow cylinder' of these exterior walls, and then slip them over your floor structures.

I thought about this and tried to work out how this would work...it seemed to me that even if I could get the wall sections to form a nice cylindrical shape and the glue seem of the two edges holds them together, they would be a tight fit around the now clear-plastic encased structures. It seemed like this had the chance of smearing glue all over the place as I try to slide the exterior wall 'cylander' over the floor structures.

Instead, I decided to just apply the exterior walls directly to the clear plastic. Apply glue to the clear plastic (outside of the window rectangle outlines of course), making sure that your window rectangles on the clear plastic align with the openings in the exterior wall (I did well on this on the 16 story section, not as well on the 11 story section!) then use tape to hold the exterior walls in position while the adhesive sets.

It does help if you flex/bend the exterior walls a bit so they will have an easier time of conforming to the cylindrical structure.

During this process, my 'full sheet' of exterior wall actually snapped apart at the seams in a couple of spots, which probably made it a little easier to apply three sections individually, rather than one sheet all at once. Anyway, if your walls snap apart like mine, no big deal, just try to align each piece the best you can and apply them separately.

These photos just illustrate the process I used to get the walls on. You'll notice in the above photo the 'rooftop' lounge section being applied to the top of the 11 story section. We'll get to that in my next post.

Stay tuned...we're almost finished!